Robotic Fabric: A Breakthrough with Many Uses

Researchers at Yale have developed a robotic fabric, a breakthrough that could lead to such innovations as adaptive clothing, self-deploying shelters, or lightweight shape-changing machinery.

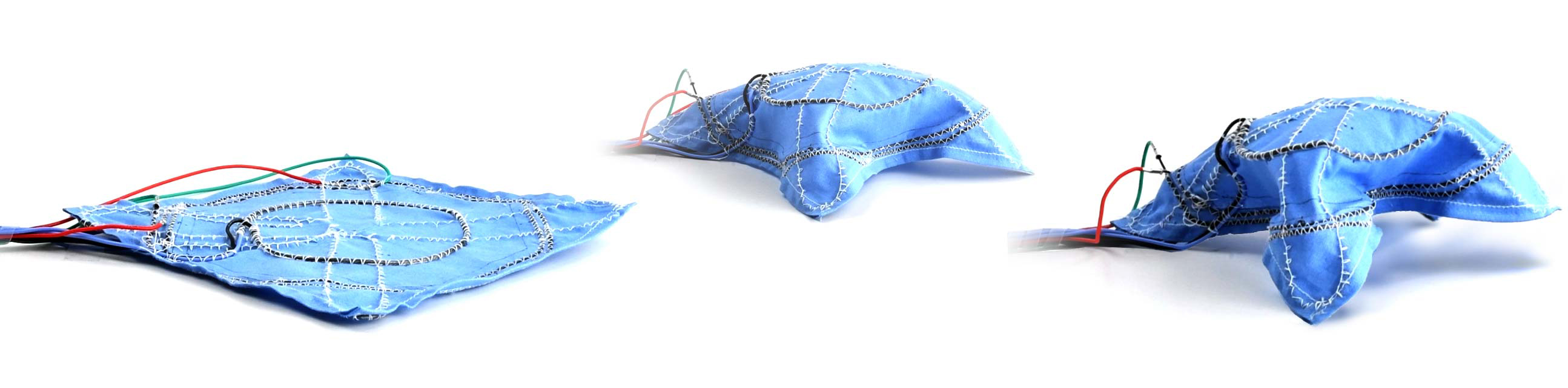

The lab of Prof. Rebecca Kramer-Bottiglio has created a robotic fabric that includes actuation, sensing, and variable stiffness fibers while retaining all the qualities that make fabric so useful - flexibility, breathability, small storage footprint, and low weight. They demonstrated their robotic fabric going from a flat, ordinary fabric to a standing, load-bearing structure. They also showed a wearable robotic tourniquet and a small airplane with stowable/deployable fabric wings. The results are published this week in Proceedings of the National Academy of Sciences.

The lab of Prof. Rebecca Kramer-Bottiglio has created a robotic fabric that includes actuation, sensing, and variable stiffness fibers while retaining all the qualities that make fabric so useful - flexibility, breathability, small storage footprint, and low weight. They demonstrated their robotic fabric going from a flat, ordinary fabric to a standing, load-bearing structure. They also showed a wearable robotic tourniquet and a small airplane with stowable/deployable fabric wings. The results are published this week in Proceedings of the National Academy of Sciences.

The researchers focused on processing functional materials into fiber-form so they could be integrated into fabrics while retaining its advantageous properties. For example, they made variable stiffness fibers out of an epoxy embedded with particles of Field’s metal, an alloy that liquifies at relatively low temperatures. When cool, the particles are solid metal and make the material stiffer; when warm, the particles melt into liquid and make the material softer.

“Our Field’s metal-epoxy composite can become as flexible as latex rubber or as stiff as hard acrylic, over 1,000 times more rigid, just by heating it up or cooling it down,” said Trevor Buckner, a graduate student in Kramer-Bottiglio’s lab and lead author on the paper. “Long fibers of this material can be sewn onto a fabric to give it a supportive skeleton that we can turn on and off.” These on-demand support fibers allow a robotic fabric to be bent or twisted and then locked into shape, or hold loads that would otherwise collapse a typical fabric.

To create sensors that detect internal or environmental changes and allow the fabric to respond appropriately, the researchers developed a conductive ink based on a Pickering emulsion, which lowers the ink viscosity and also enables the use of non-toxic solvents. With this ink, the researchers can paint the sensors directly onto the fabric.

“The conductive composite self-coagulates around the individual fibers and does not notably change the porosity of the fabric,” said Kramer-Bottiglio, the John J. Lee Assistant Professor of Mechanical Engineering & Materials Science. “The sensors are visible, but don’t change the texture or breathability of the fabric, which is important for comfort in wearable applications.”

To make the fabric move, the researchers used shape-memory alloy (SMA) wire, which can return to a programmed shape after being deformed. SMA wire is usually programmed into coils or meshes to generate contracting motion, but this approach was not desirable as it caused the fabric to bunch up unpredictably.

“Instead of using the coil technique, we flattened the wires out into ribbons to give them a geometry much more suited to smooth bending motion, which is perfect for robotic fabrics,” said Buckner.

As the project was funded by the Air Force Office of Science Research, the researchers envision applications such deployable and adaptive structures, active compression garments, smart cargo webbing, and reconfigurable RF antennas. “We believe this technology can be leveraged to create self-deploying tents, robotic parachutes, and assistive clothing,” says Kramer-Bottiglio. “Fabrics are a ubiquitous material used in a wide range of products, and the ability to ‘roboticize’ some of these products opens up many possibilities.”